Tailor-made technical support from Concept to Operation

SANYO DENKI Europe S.A.

TECHNICAL CENTER

11 rue Ferdinand de Lesseps, 95190 Goussainville, France | TEL: +33 1 4863 2661

SANYO DENKI Europe S.A. Technical Center is located in Goussainville, France. Tailored Solutions for Performance-Driven Applications in Europe

At SANYO DENKI Europe, we specialize in customized motor and cooling fan development, delivering engineered-to-order motion and thermal management solutions to meet your specific application requirements.

Whether you require precise airflow, torque, speed, low-noise operation, or environmental resistance, our European Technical Center works closely with you to co-develop optimized, high-efficiency motors and cooling systems.

Why Choose Our Technical Center in Europe?

Customization

Tailored to Your Application. We design and engineer motors and cooling fans that precisely match your performance, size, and environmental constraints.

Integration

Integrated Motor and Cooling Fan Solutions from shaft geometry and gearbox to cabling, fan tray integration, we provide customized service— carefully selected to ensure optimal motion control and thermal management.

Support

Local Engineering & Rapid Prototyping in Europe. Our multilingual engineering team supports your product lifecycle, offering quick feasibility studies, design validation, and custom assembly guidance.

Reliability

Field-Proven Reliability Across Industries Our cooling and motion systems are trusted in automation, robotics, medical devices, EV charging, agriculture, and more.

Tailored Solutions for People In Motion

|

|

|

|---|---|

|

|

|

|

|

|

Support Cases

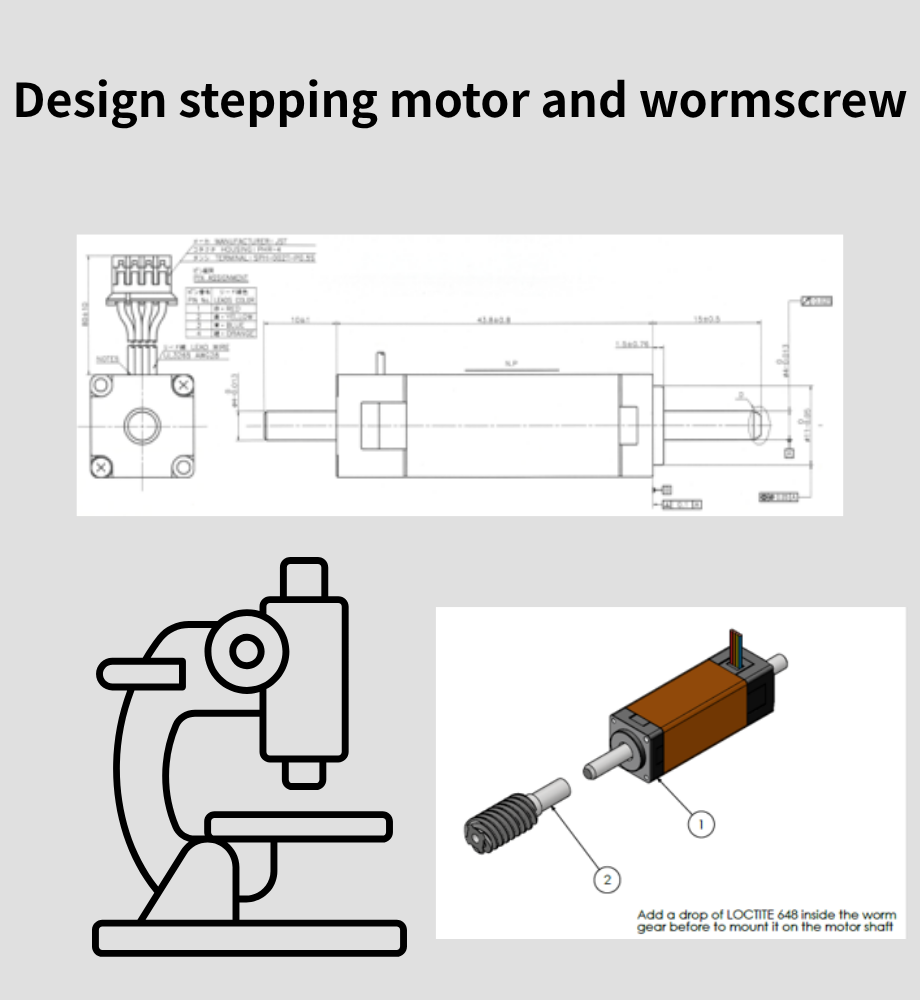

| Technical Center Support Case 01: | |

|---|---|

| Design stepping motor and Wormscrew | |

|

Purposal : 14mm square stepping motor with higher allowable torque + JST connector cabling for Linear translation stages Engineering support: Cabling definition with customer. Gluing process during motor’s bearing insertion : Allowable thrust load up to 10N. Additional customization : -Worm screw supplying - Worm screw + motor assembled by Gluing process. |

| Technical Center Support Case 02: | |

|---|---|

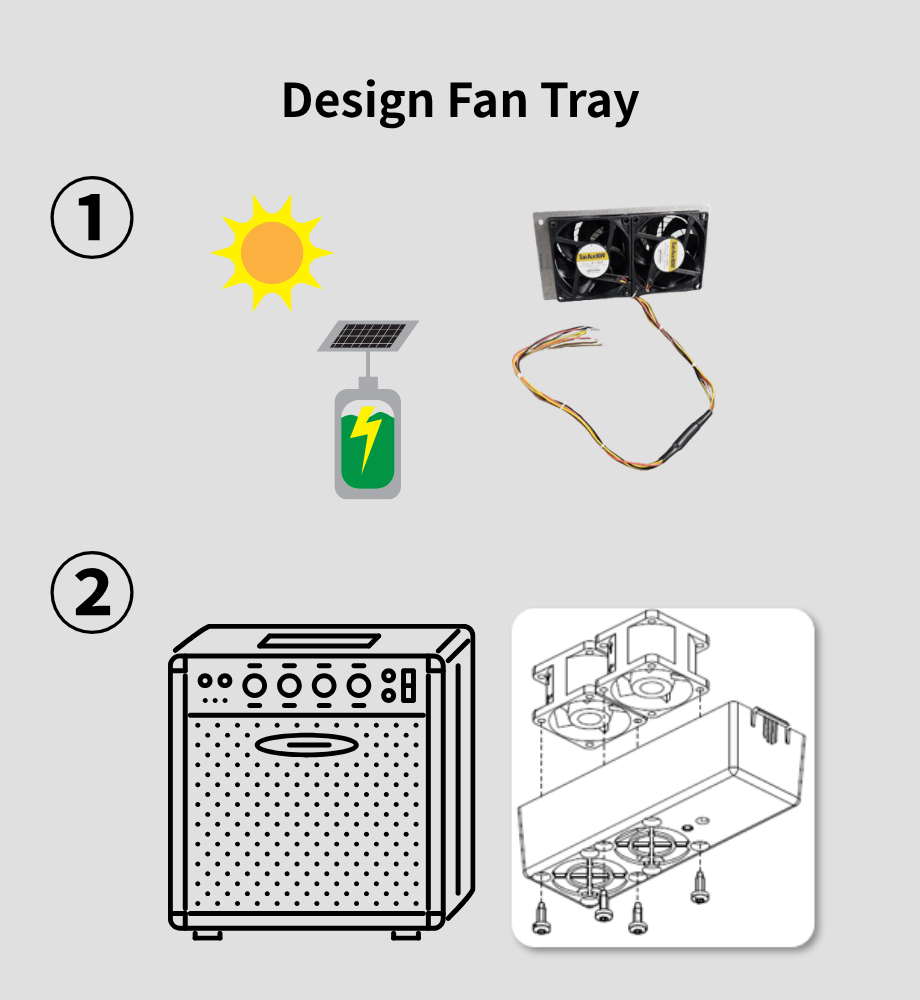

| Design Fan Tray | |

|

1) Customer’s fan plate design support and finalize different fan options Fans cabling definition New local supplier for inox fan plate EAR fan mounting 2) Box integration proposal Customized cabling AML plastic injected part |

| Technical Center Support Case 03: |

|---|

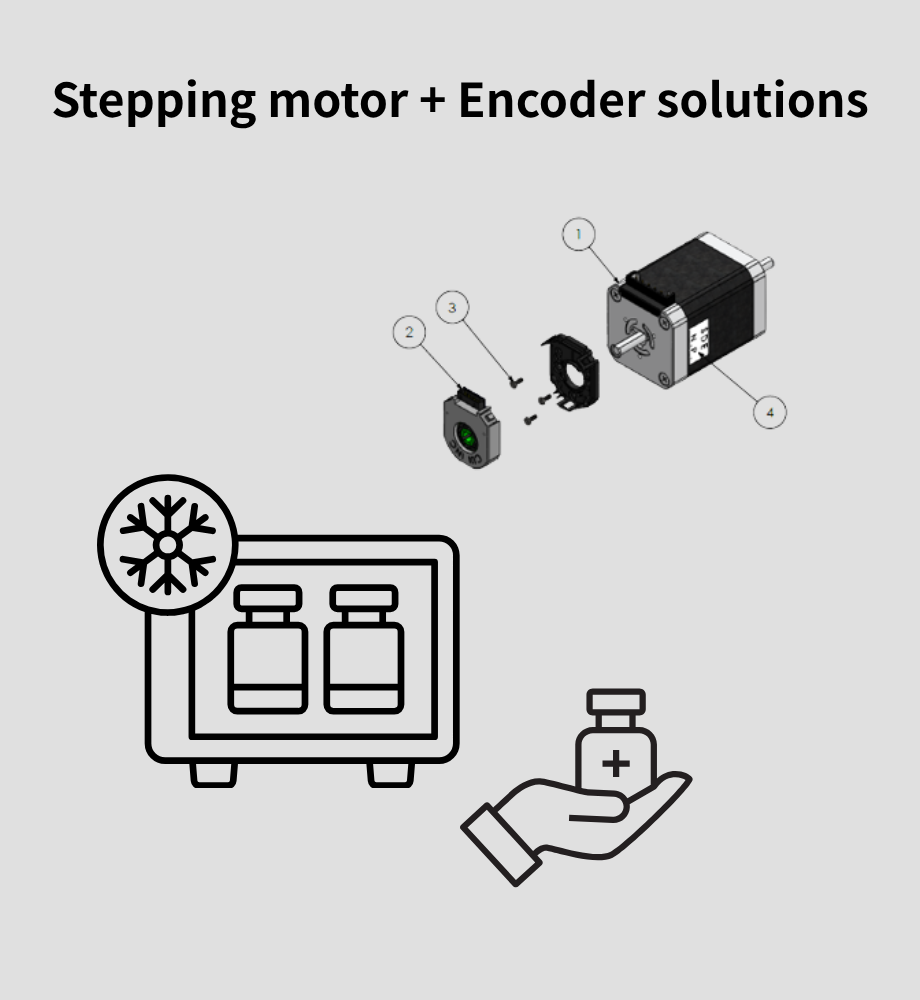

| Stepping motor + encoder solutions |

|

For Application Medical Device -Motors selection and machining for encoder adaptation. -Definition of programmable 5VDC 4096ppr encoder line driver. -Workbench development for Stepping motor rotation + high resolution encoder counting. -Implementation of new F2 driver F2BED200P100 on workench. -Arduino Microcontroller boards implementation for encoder reading. |

| Technical Center Support Case 04: | |

|---|---|

|

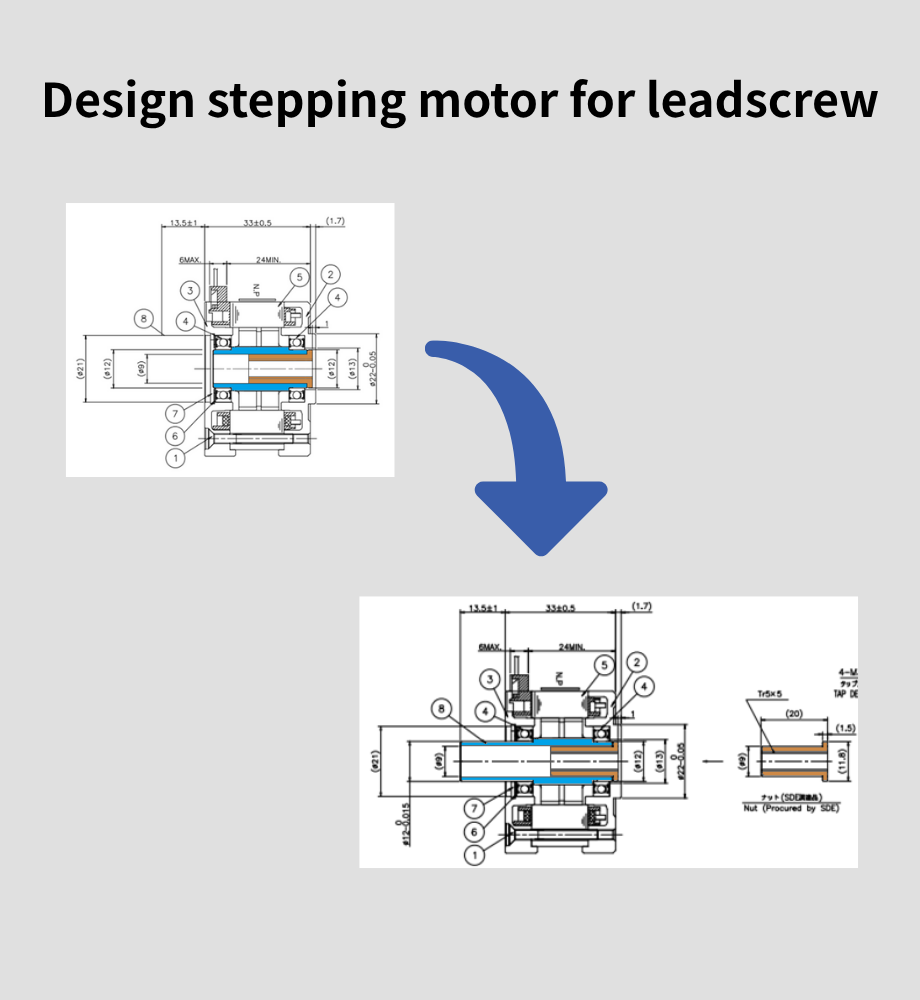

Design stepping motor for leadscrew : New hollow shaft motor inner Dia 9 - insert as an option

|

|

|

Flexible solutions : -large inner diameter to propose multiple designs -Adaptive insert according to customer's requests : Pitch & Diameter -Easy to adapt encoder -Increasing allowable thrust laod 60N or more |